What are the characteristics and advantages of precision CNC machining

1. Characteristics

high-precision:

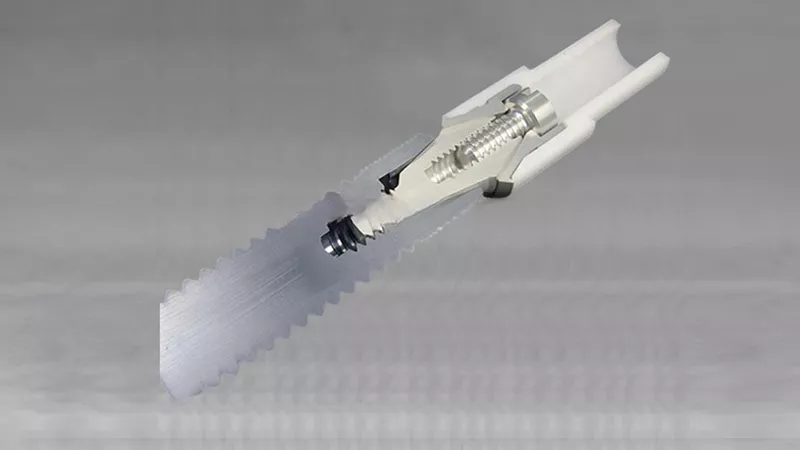

Precision CNC machining can achieve precise control of tool position and movement speed through high-precision CNC systems, thus machining parts within the micrometer level accuracy range. This high-precision implementation is due to the advanced servo motors, ball screw pairs, and precise transmission mechanisms used in CNC machine tools.

The machining dimensional accuracy can usually reach between d0.005-0.01mm, and is not affected by the complexity of the parts.

High efficiency:

CNC machining has the characteristics of automation and continuity, which can achieve high-speed and efficient machining processes. Through reasonable tool path planning and multi axis motion control, production efficiency and machining speed can be significantly improved.

Automated control reduces manual intervention time, allowing machine tools to operate continuously and significantly improving production efficiency.

Multifunctionality:

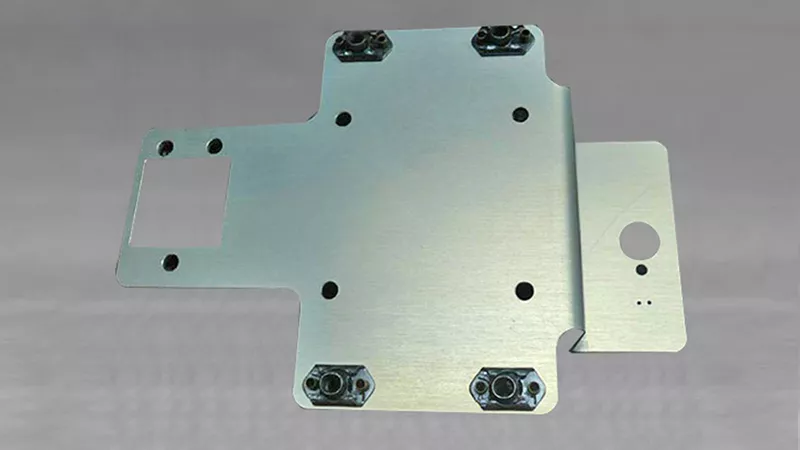

CNC machining equipment can perform various types of machining operations, such as milling, turning, drilling, boring, tapping, etc., and can adapt to the requirements of different parts and processes.

This multifunctionality makes CNC machining highly flexible and adaptable, capable of meeting the machining needs of complex parts.

Good repeatability:

CNC machining can achieve repetitive machining under the same process parameters through computer program control. Each processing result is consistent, ensuring product consistency and stability, and reducing the impact of human factors on processing quality.

Programmability:

CNC machining equipment has the characteristics of automation control, which can reduce manual intervention and operation, lower labor costs and labor intensity. At the same time, automated control also improves the safety and comfort of the working environment.

Processing workshops typically use CAM (Computer Aided Manufacturing) software to automatically read CAD (Computer Aided Design) files and generate G-code programs to control CNC machine tools.

2. Advantages

Strong adaptability:

When changing the processing object, in addition to changing the cutting tool and solving the blank clamping method, only reprogramming is needed without other complex adjustments, shortening the production preparation cycle.

Suitable for small-scale and multi variety production modes, it can effectively reduce production preparation time and costs.

Stable processing quality:

Due to the fact that most operations are automatically completed by machines and precise transmission mechanisms and position detection devices are used, the machining quality is stable and reliable.

Precision CNC machining can achieve strict tolerance requirements and maintain consistency in product quality.

Widely applicable fields:

Precision CNC machining is widely used in fields such as automotive, aviation, medical, military, and scientific research, especially suitable for processing complex and high-precision parts.

For example, in the field of aviation and aerospace, CNC precision machining is used to manufacture engine components, fuselage structural parts, and other critical components; In automobile manufacturing, it is used to process high-precision components such as engine parts and transmission gears.

Complete technical services:

Many CNC machining manufacturers provide full process services from design to finished products, including process planning, programming, machining, testing, and post-processing.

By obtaining ISO 9001 and other quality management system certifications, we ensure that process control and product quality comply with international standards.